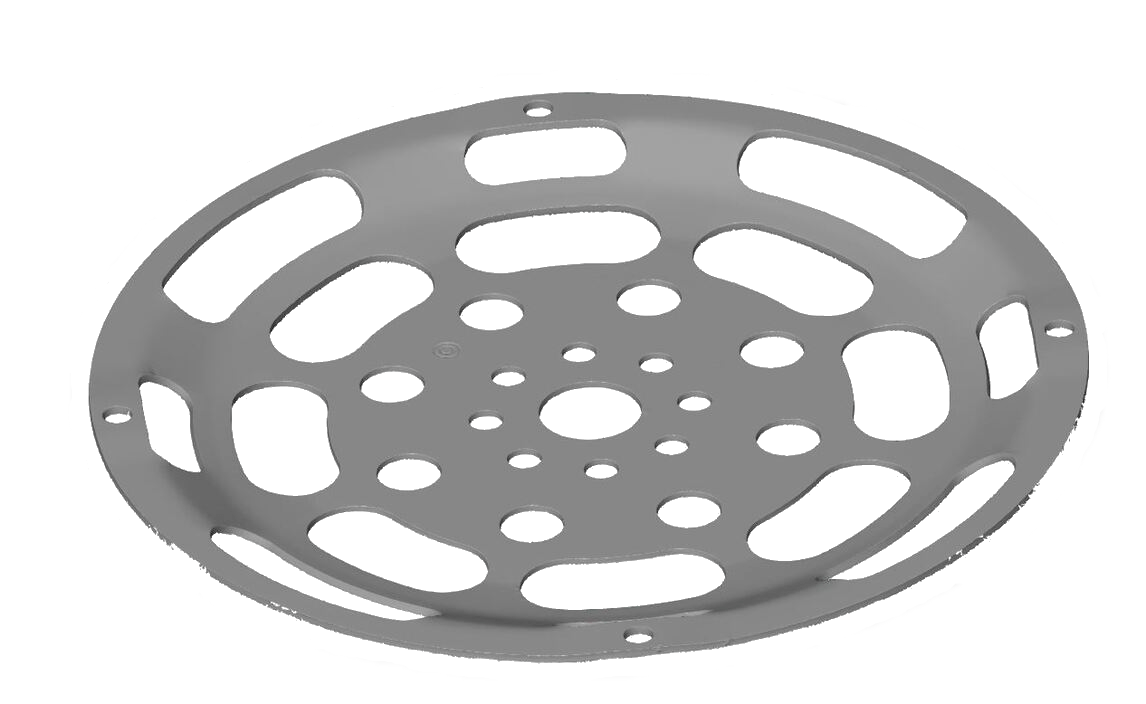

High precision die design and manufacturing. Progressive, Transfer, etc. up to 4000mm and 20 tons.

High precision plastic mold design and manufacturing.

We can also fabricate jigs for checking fixtures (go/no-go gauges) and to assist in tool alignment.

Custom die and mold components / spare parts.

Beyond tooling, Sanko Seiki also can manufacture parts and components to your specifications.

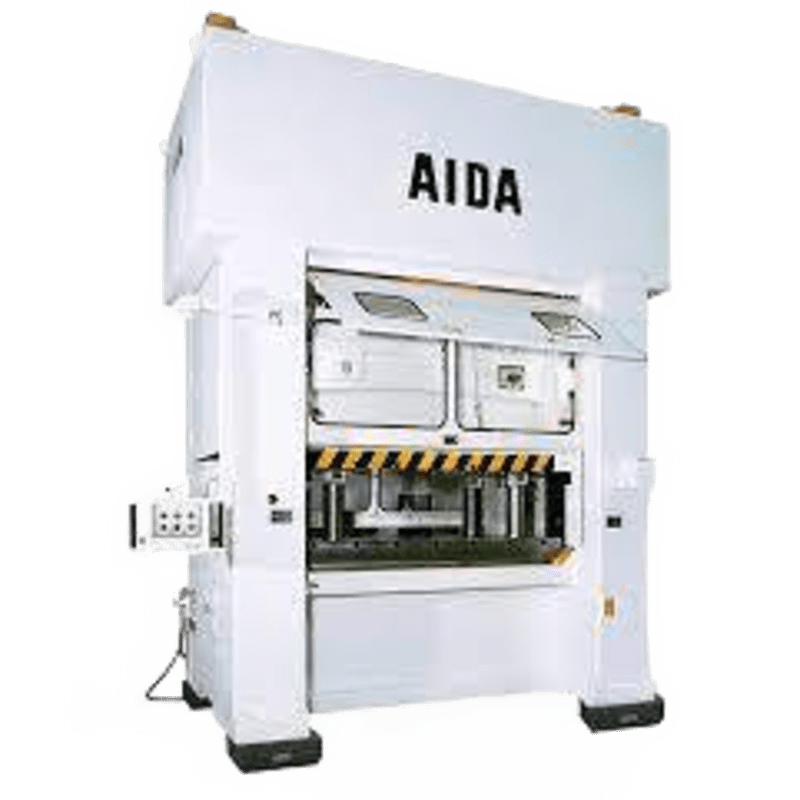

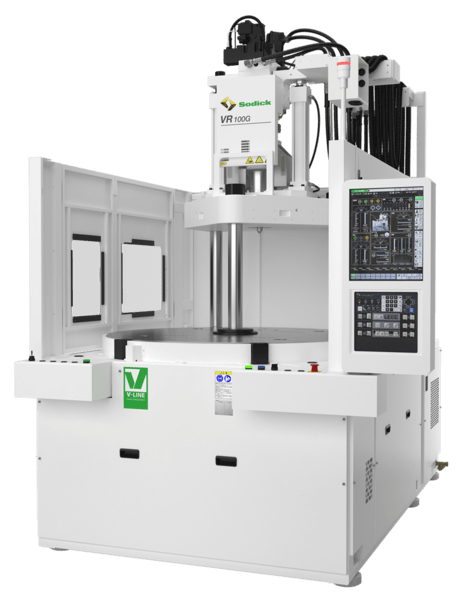

We can do both custom Progressive Dies with capabilities of up to 1200 metric ton in addition to being able to design and supply custom Plastic Insert Molds.

With Sanko Seiki's Stamping Presses we can thoroughly check and validate dies. Additionally, Sanko Seiki can produce parts and components to order.

With our Vertical Injection Mold equipment, Sanko Seiki can make and validate a variety of insert molds. Together with our stamping presses, we can custom-build insert parts for molding.

Sanko Seiki's Q&A process features a high-speed non-contact measurement system to validate forms.

During the engineering process Sanko Seiki designers will simulate the stamping process to quickly identify defects or deviations to streamline and augment the design process.

Through Sanko Seiki's unique processes and capabilities, we can offer superior lead time and maximum value.

We pair you with our engineering teams as we go together, step-by-step, through the simulation, prototyping, and part validation.

We pair you with our engineering teams as we go together, step-by-step, through the simulation, prototyping, and part validation.

Our press forming analysis software (J-STAMP) enables us to identify anomalies before they become time consuming problems. This translates into:

Through these simulations, our engineers can visualize spring back and determine the optimum process to correct these deficiencies.

After a series of trial production runs, samples are 3D scanned for deviations from the simulated data. Anomalies are analyzed and the necessary modifications are implemented.

Our craftsmen and engineers tirelessly strive for perfection.

We work on your schedule and understand that time is money.

We deliver quality and value to your product.

Since 1952, we’ve embraced innovation and molded it with our crafting tradition.

Since 1952 Sanko Seiki has been in the business of press dies, die parts, prototype production, automotive parts production.

Sanko Seiki is a multinational company reaching for the future and we want you to be a part of it, a part of us.

Take the next step and contact our office today at <join@sanko-seiki.com>

Let’s do this together.

1-1, Tedikara-cho, Gifu City, Gifu Prefecture, Japan 500-8236

TEL:

+81 (058) 247-4466

FAX:

+81 (058) 247-4467

E-MAIL:sales@sanko-seiki.com

C/O LINCOLN MANUFACTURING USA, LLC

102 Industrial Park Drive,

Stanford, Kentucky, USA 40484

TEL:

+1 (859) 516-5552

+81 (50)-3696-3599

E-MAIL:sui@sanko-seiki.com